All PCB designers – whether rigid, bendy, or inflexible flex – use these files to talk to PCB manufacturers exactly how they want their forums constructed. They include one more object that is essential for the PCB fabricator – a fabrication print. The fabrication print cautiously info all the requirements of the forums, that are not within the gerber files. The fabrication print as an example will detail what substances we’re to use constructing their board, what size drilled holes they would really like, any unique manufacturing instructions or specs we want to satisfy, and miscellaneous facts like what color soldermask or nomenclature they would love.

With these additives, we will build a custom board, that meets the purchaser’s requirements exactly. As PCBs are particularly customizable, they can be designed and synthetic to diverse flexibilities, sizes, and configurations to match nearly any software.

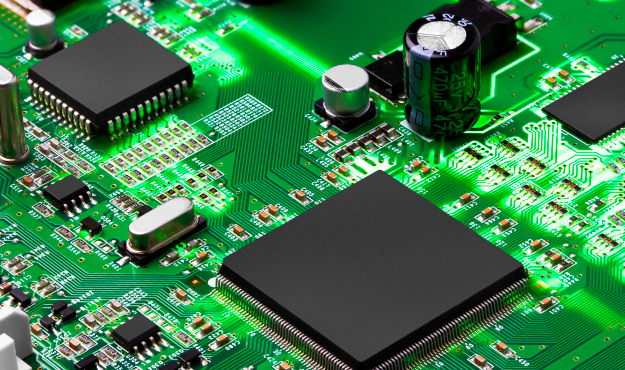

Printed Circuit Board Materials The number one materials used in the manufacture of PCBs are fiberglass or plastic substrates, copper, solder masks, and nomenclature ink.

Fiberglass & Plastic Substrates PCBs may be built on inflexible or bendy base materials depending on the meant PCB layout. Rigid PCB regularly use FR4 or polyimide fiberglass, even as flexible circuits and rigid-flex flexible layers typically use excessive-temperature polyimide movies.

Common plastic substrates for bendy circuits consist of polyimide (PI), liquid crystal polymer (LCP), polyester (PET), and polyethylene naphthalate (PEN). The motive of the substrate is to provide a non-conductive base upon which the conductive circuits may be built and insulated from one another. Polyimide and LCP laminates are normally used in excessive reliability or excessive sign pace packages. Polyester and polyethylene napthalate laminates are in most cases selected for their low value, and normally are just unmarried layers of circuitry.

Copper Due to its high electrical conductivity, copper is the most used engaging in material for circuitry in PCBs. The laminates defined above, all come with skinny sheets of copper foil laminated to at least one or each aspects of the plastic. The fabricator then makes use of the gerber files provided by way of the fashion designer, to photo and etch the circuits to meet the purchaser’s requirements. The thickness and wide variety of layers required are largely established upon the application for which the PCB could be used. Multi-layered PCBs are constructed with the aid of alternating layers of copper circuitry and insulating substances to complete the PCB.

Soldermask Soldermask is a liquid, normally an epoxy fabric, this is implemented onto the outerlayers of rigid PCBs. It is also commonly used on the inflexible sections of inflexible flex PCB’s. Soldermask is in general designed to insulate the copper circuits on outerlayers from oxidation from the surroundings. Soldermask is also designed to manipulate and preserve the waft of solder whilst the components are assembled to the PCB. Without soldermask, the liquid solder could flow out onto the floor of the PCB, connecting two adjacent circuits and brief out the board. The maximum not unusual colour for soldermask is inexperienced, but blue, black, purple, amber, clean, white and plenty of other colours exist as nicely.